3D Printing Software

In the fast-evolving landscape of technology, 3D printing has emerged as a revolutionary force, transforming the way we manufacture and create objects. From intricate prototypes to personalized consumer products, the applications of 3D printing are vast and diverse. However, behind the scenes, 3D printing software plays a pivotal role in turning digital designs into tangible, three-dimensional objects. In this blog post, we will delve into the world of 3D printing software, exploring its types, features, and the impact it has on the entire 3D printing process.

Understanding 3D Printing Software

At its core, 3D printing software acts as the bridge between a digital 3D model and the physical object that emerges from the 3D printer. These software tools are responsible for translating intricate digital designs into a format that 3D printers can understand and execute layer by layer. The primary functions of 3D printing software include slicing the digital model into layers, generating support structures, and providing control over the printing parameters.

Types of 3D Printing Software

- CAD Software (Computer-Aided Design):

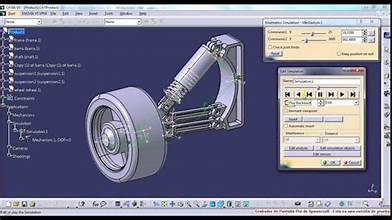

- CAD software is where the journey begins for many 3D printing enthusiasts and professionals. Programs like AutoCAD, SolidWorks, and Fusion 360 allow users to create detailed 3D models, defining every aspect of the object they intend to print.

- Slicing Software:

- Once the 3D model is ready, it needs to be sliced into layers – a crucial step for the 3D printer to comprehend the printing instructions. Slicing software, such as Cura, Simplify3D, and PrusaSlicer, takes care of this process, allowing users to customize layer thickness, infill patterns, and support structures.

- Printer Firmware:

- While not traditionally classified as software, the firmware embedded in the 3D printer itself is a critical component. It interprets the G-code generated by the slicing software and controls the movement of the printer’s motors, extruders, and other components.

Key Features of 3D Printing Software

- User-Friendly Interface:

- Many 3D printing software tools prioritize user experience, offering intuitive interfaces that cater to both beginners and experienced users. Simplified navigation and clear options enhance the overall usability of the software.

- Customization Options:

- Advanced users often appreciate software that provides a wide range of customization options. This includes settings for layer thickness, infill density, print speed, and support structures, allowing for precise control over the printing process.

- Multi-Material Support:

- As 3D printing technology advances, so does the demand for multi-material printing. Some software solutions now support the use of different materials within a single print job, opening up new possibilities for creating complex and diverse objects.

- Cloud Integration:

- With the rise of cloud computing, several 3D printing software tools offer cloud integration. This feature enables users to store and access their designs remotely, collaborate with others, and even send print jobs to their 3D printers from anywhere in the world.

- Real-Time Monitoring:

- Certain 3D printing software provides real-time monitoring capabilities. Users can track the progress of their print jobs, receive alerts for any issues, and even make adjustments on the fly, ensuring a smoother and more efficient printing process.

Impact on 3D Printing Industry

The evolution of 3D printing software has significantly influenced the 3D printing industry as a whole. Here are some notable impacts:

- Accessibility:

- User-friendly interfaces and intuitive controls have made 3D printing more accessible to a broader audience. Hobbyists, educators, and small businesses can now harness the power of 3D printing technology without extensive technical expertise.

- Innovation:

- Advanced features in 3D printing software have spurred innovation in design and manufacturing. Complex geometries, intricate patterns, and multi-material prints are now within reach, pushing the boundaries of what can be achieved with 3D printing.

- Collaboration:

- Cloud integration has facilitated collaboration among designers, engineers, and enthusiasts. Teams can work on projects simultaneously, share designs seamlessly, and contribute to the growth of the 3D printing community.

- Efficiency:

- Real-time monitoring and remote control features have improved the efficiency of 3D printing operations. Users can troubleshoot issues, adjust settings, and optimize print parameters without being physically present, saving time and resources.

Conclusion

In conclusion, 3D printing software is the unsung hero behind the remarkable creations that emerge from 3D printers. From conceptualization to realization, these software tools play a crucial role in shaping the future of manufacturing, design, and innovation. As technology continues to advance, we can only anticipate further enhancements in 3D printing software, unlocking new possibilities and pushing the boundaries of what can be achieved in the world of three-dimensional printing.